Heat Treating Resources

Knowledge is the key to success in the competitive heat treating industry.

Below is a collection of charts and tables that should answer most frequently asked questions regarding our services.

If you still have questions, please contact us and we'll do our best to help.

NADCAP Certificate

General Temper Conversions Chart for 7075 Material.

The 7075 Material is listed on the horizontal axis and the Starting Mill Temper on the vertical axis.

| "0" | "01" | T6 | T651 | T6511 | T73 | T7351 | T73511 | T76 | T7651 | T76511 | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| "0" | --- |  |

** ** |

|

|

** ** |

|

|

** ** |

|

|

| T6 |  |

|

--- |  |

|

|

|

|

|

|

|

| T651 |  |

|

** ** |

--- |  |

** ** |

|

|

** ** |

|

|

| T6511 |  |

|

** ** |

|

--- |  ** ** |

|

|

** ** |

|

|

| T73 |  |

|

** ** |

|

|

--- |  |

|

** ** |

|

|

| T7351 |  |

|

** ** |

|

|

** ** |

--- |  |

** ** |

|

|

| T73511 |  |

|

** ** |

|

|

** ** |

|

--- |  ** ** |

|

|

| T76 |  |

|

** ** |

|

|

** ** |

|

|

--- |  |

|

| T7651 |  |

|

** ** |

|

|

** ** |

|

|

** ** |

--- |  |

| T76511 |  |

|

** ** |

|

|

** ** |

|

|

** ** |

|

--- |

Notes: ** Can be achieved by resolution and/or resolution and artificial age. This process can cause distortion depending on material thickness and configuration.

General Temper Conversions Chart for 2024 Material.

The 2024 Material is listed on the horizontal axis and the Starting Mill Temper on the vertical axis.

| "0" | T3 | T351 | T3511 | T4 | T42 | T6 | T62 | T81 | T851 | T8511 | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| "0" | --- |  |

|

|

** ** |

** ** |

** ** |

** ** |

|

|

|

| T3 |  |

--- |  |

|

** ** |

** ** |

** ** |

** ** |

|

|

|

| T351 |  |

|

--- |  |

** ** |

** ** |

** ** |

** ** |

|

|

|

| T3511 |  |

|

|

--- |  ** ** |

** ** |

** ** |

** ** |

|

|

|

| T4 |  |

|

|

|

--- |  ** ** |

|

** ** |

|

|

|

| T42 |  |

|

|

|

** ** |

--- |  ** ** |

|

|

|

|

| T6 |  |

|

|

|

** ** |

** ** |

--- |  ** ** |

|

|

|

| T62 |  |

|

|

|

** ** |

** ** |

** ** |

--- |  |

|

|

| T81 |  |

|

|

|

** ** |

** ** |

** ** |

** ** |

--- |  |

|

| T851 |  |

|

|

|

** ** |

** ** |

** ** |

** ** |

|

--- |  |

| T8511 |  |

|

|

|

** ** |

** ** |

** ** |

** ** |

|

|

--- |

Notes: ** Can be achieved by resolution and/or resolution and artificial age. This process can cause distortion depending on material thickness and configuration.

General Temper Conversions Chart for 6061 Material.

The 6061 Material is listed on the horizontal axis and the Starting Mill Temper on the vertical axis.

| "0" | T4 | T42 | T6 | T62 | |

|---|---|---|---|---|---|

| "0" | --- |  ** ** |

** ** |

** ** |

** ** |

| T4 |  |

--- |  ** ** |

|

** ** |

| T42 |  |

** ** |

--- |  ** ** |

|

| T6 |  |

** ** |

** ** |

--- |  ** ** |

| T62 |  |

** ** |

** ** |

** ** |

--- |

Notes: ** Can be achieved by resolution and/or resolution and artificial age. This process can cause distortion depending on material thickness and configuration.

General Temper Conversions Chart for 7075 Material.

The 7075 Material is listed on the horizontal axis and the Starting Mill Temper on the vertical axis.

| C Scale |

A Scale |

15-N Scale |

KSI (PSI) |

C Scale |

A Scale |

15-N Scale |

KSI (PSI) |

C Scale |

A Scale |

15-N Scale |

KSI (PSI) |

||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 80 | 92 | 96.5 | --- | 60 | 81.2 | 90.2 | --- | 40 | 70.4 | 80.9 | 182 | ||

| 79 | 91.5 | 96.3 | --- | 59 | 80.7 | 89.8 | 351 | 39 | 69.9 | 79.9 | 177 | ||

| 78 | 91 | 96 | --- | 58 | 80.1 | 89.3 | 338 | 38 | 69.4 | 79.4 | 171 | ||

| 77 | 90.5 | 95.8 | --- | 57 | 79.6 | 88.9 | 325 | 37 | 68.9 | 78.8 | 166 | ||

| 76 | 90 | 95.5 | --- | 56 | 79 | 88.3 | 313 | 36 | 68.4 | 78.3 | 161 | ||

| 75 | 89.5 | 95.3 | --- | 55 | 78.5 | 87.9 | 301 | 35 | 67.9 | 77.7 | 156 | ||

| 74 | 89 | 95 | --- | 54 | 78 | 87.4 | 292 | 34 | 67.4 | 77.7 | 156 | ||

| 73 | 88.5 | 94.8 | --- | 53 | 77.4 | 86.9 | 283 | 33 | 66.8 | 76.6 | 149 | ||

| 72 | 88 | 94.5 | --- | 52 | 76.8 | 86.4 | 273 | 32 | 66.3 | 76.1 | 146 | ||

| 71 | 87 | 94.3 | --- | 51 | 76.3 | 85.9 | 264 | 31 | 65.8 | 75.6 | 141 | ||

| 70 | 86.5 | 94 | --- | 50 | 75.9 | 85.5 | 255 | 30 | 65.3 | 75 | 138 | ||

| 69 | 86 | 93.5 | --- | 49 | 75.2 | 85 | 246 | 29 | 64.6 | 74.5 | 135 | ||

| 68 | 85.6 | 94 | --- | 48 | 74.7 | 84.5 | 238 | 28 | 64.3 | 73.9 | 131 | ||

| 67 | 85 | 92.9 | --- | 47 | 74.1 | 83.9 | 229 | 27 | 63.8 | 73.3 | 128 | ||

| 66 | 84.5 | 92.5 | --- | 46 | 73.6 | 83.5 | 221 | 26 | 63.3 | 72.8 | 125 | ||

| 65 | 83.9 | 92.2 | --- | 45 | 73.1 | 83 | 215 | 25 | 62.8 | 72.2 | 123 | ||

| 64 | 83.4 | 91.8 | --- | 44 | 72.5 | 82.5 | 208 | 24 | 62.4 | 71.6 | 119 | ||

| 63 | 82.8 | 91.4 | --- | 43 | 72 | 82 | 201 | 23 | 62 | 71 | 117 | ||

| 62 | 82.3 | 91.1 | --- | 42 | 71.5 | 81.5 | 194 | 22 | 61.5 | 70.5 | 115 | ||

| 61 | 92 | 81.8 | --- | 41 | 70.9 | 80.9 | 188 | 21 | 61 | 69.9 | 112 | ||

| 20 | 60.5 | 69.4 | 110 |

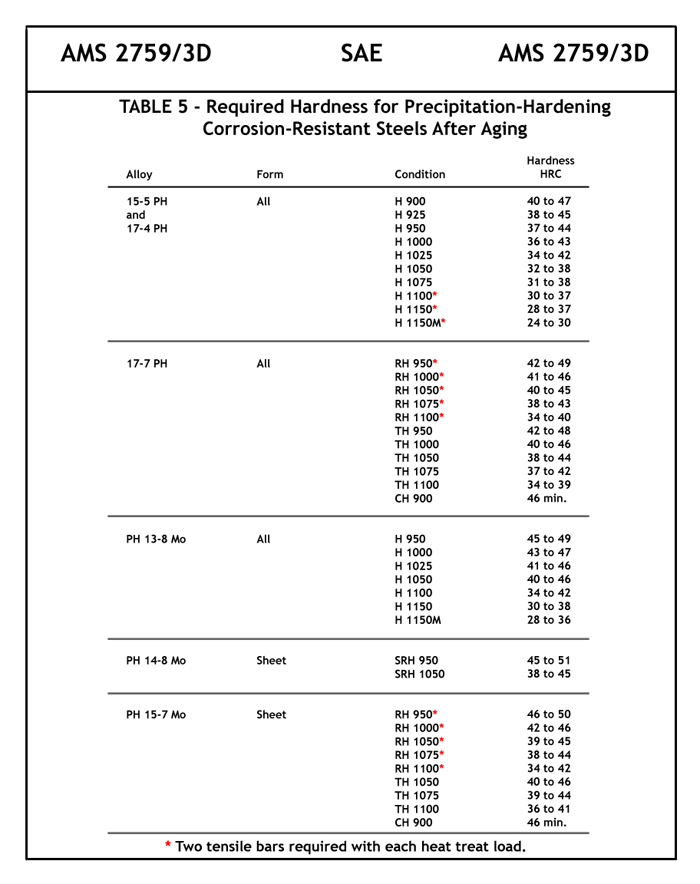

Required hardness for precipitation-hardening corrosion-resistant steels after aging.

Table adapted from SAE AMS 2759/3D Table 5.